Our EV Addiction Has a Dirty Secret: The True Environmental Cost of Lithium Mining

The electric vehicle (EV) is the gleaming symbol of our green future. Sleek, silent, and tailpipe-free, it represents a decisive break from the fossil-fueled past. Governments around the world are pouring subsidies into EV adoption, and consumers are responding, driving a global transition away from the internal combustion engine. This revolution is powered by the lithium-ion battery, a marvel of electrochemical engineering. But hidden behind the clean facade of the EV lies a dirty secret: the extraction of lithium, the battery's essential ingredient, carries a heavy environmental and social price tag. As we rush to electrify everything, we risk trading one form of extraction for another, creating new sacrifice zones in the name of climate progress.

Lithium, the lightest metal on Earth, is found primarily in two types of deposits. In Australia, the world's largest producer, it is extracted from hard-rock mines, a process that involves open-pit mining, crushing the rock, and using chemicals to separate the lithium. This is an energy-intensive process that leaves behind massive scars on the landscape and large tailings ponds of chemical waste. The second major source is the "Lithium Triangle" in the Andes mountains of Argentina, Bolivia, and Chile. Here, lithium is found in salty brine deep beneath desert salt flats. The extraction process involves pumping this brine to the surface and letting it evaporate in massive ponds for months, eventually leaving behind a concentration of lithium salts.

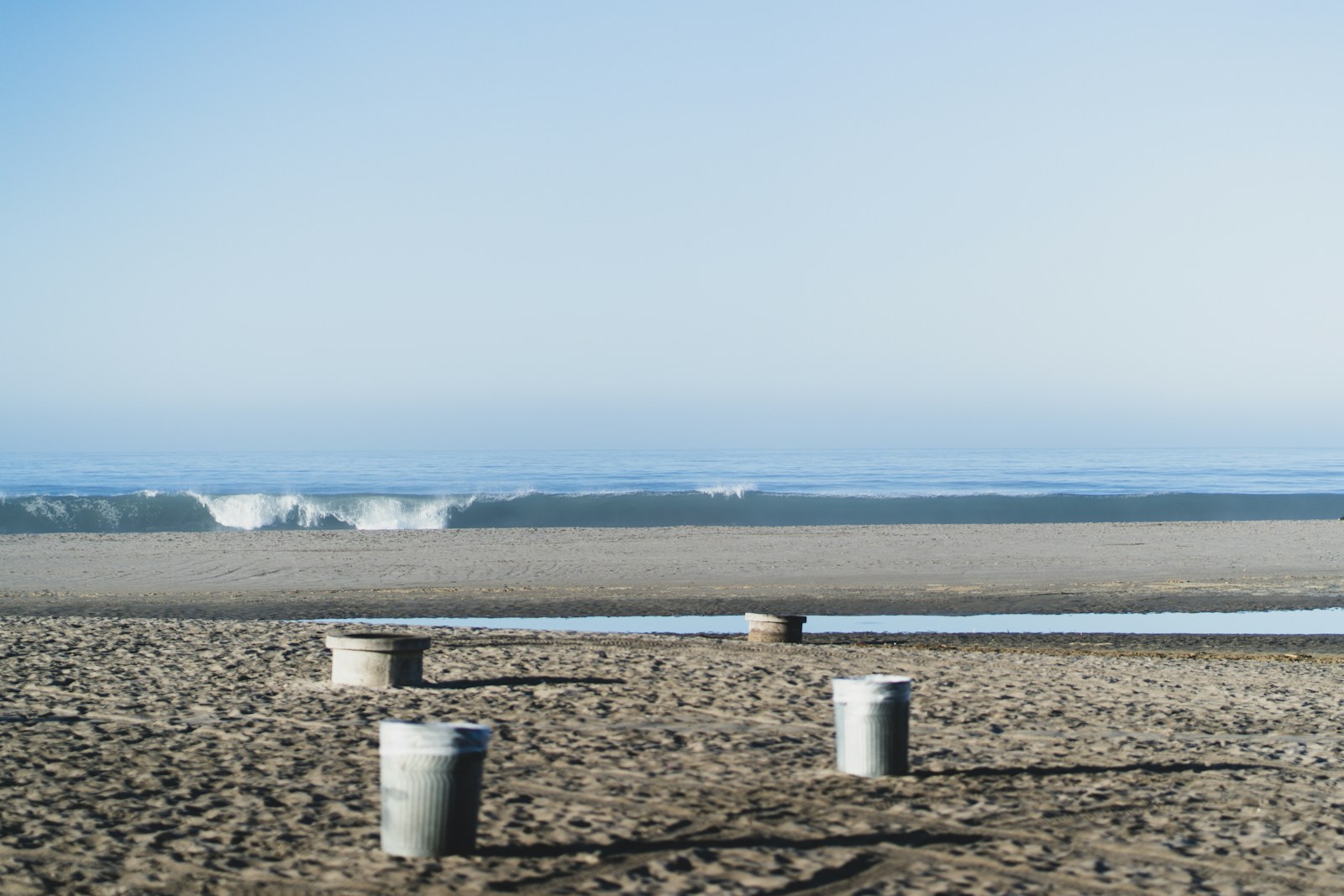

This brine-evaporation method, while less visually destructive than hard-rock mining, has a devastating hidden cost: water. The Atacama Desert, where much of this mining occurs, is one of the driest places on Earth. Lithium extraction consumes vast quantities of water—up to 500,000 gallons per ton of lithium—in a region where indigenous communities and fragile ecosystems are already struggling with water scarcity. This has led to conflicts over water rights, with local communities reporting that their ancestral lands are drying up, impacting their ability to farm and raise livestock. The process also risks contaminating the remaining freshwater sources with the chemicals used in processing.

This presents a profound ethical and engineering dilemma. How can we call a technology "green" if its supply chain devastates ecosystems and dispossesses communities? The answer lies not in abandoning EVs, but in fundamentally rethinking the battery lifecycle. The first line of attack is to reduce demand for newly mined materials. This means investing heavily in battery recycling. Currently, less than 5% of lithium-ion batteries are recycled globally. Improving this rate requires designing batteries for easier disassembly and developing more efficient hydrometallurgical and pyrometallurgical processes to recover not just lithium, but also the cobalt, nickel, and manganese inside them. A robust recycling industry would create a secure, domestic source of battery materials, reducing our reliance on fragile and geopolitically concentrated global supply chains.

The second frontier is innovation in battery chemistry. Researchers and startups are racing to develop next-generation batteries that use more abundant and less environmentally damaging materials. Sodium-ion batteries, for instance, use common salt instead of lithium and are showing increasing promise for stationary storage and even some EV applications. Solid-state batteries, another promising technology, could offer higher energy density with fewer rare materials.

The EV revolution is a critical component of our climate strategy. But a truly sustainable transition cannot be built on a foundation of destructive extraction. We must apply the same innovative spirit that created the electric car to solving the problems of its supply chain. This means pushing for a circular battery economy through recycling, investing in alternative chemistries, and demanding that mining companies adhere to the highest environmental and social standards. Without this holistic approach, we are not solving our problem, merely outsourcing it to a different part of the planet.